The Swan Creek Railroad

NOTE: This article is reprinted with revisions, from the Division 1, NCR NMRA newsletter, the “Train Order”, Vol #98 February 2025 While looking at historical…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print

Shoebox Layout Ideas

In Episode 47 of the Cartel Conversations Podcast, the hosts, Ian Holmes and Tom Conboy, introduced the 2024 Micro Model Railway Cartel Challenge. For 2024…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print

Pizzatopia – an HOn30 Micro Layout

For the last couple years, the e-magazine The Micro Model Railway Dispatch and the Facebook group Micro Model Railroad Cartel have been hosting an annual…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print

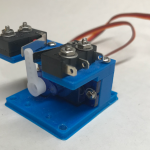

SERVO MOUNTING BRACKETS ARE BACK!

After some work on the site, I have the servo mounting brackets available again. The old plugin just stopped working and would take the whole…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print

Small Layout Meet 2023

Back in June I managed to take time to travel to Findlay and the 2023 Small Layout Meet. While there I tried to video document…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print

Website Issues (again)

I recently had an issue with the eCommerce software I have been using to sell the Servo Brackets. The website kept working to the public…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print

Jackson Belt Line, a Small Prototype for Any Era – Part I

Where is the Jackson Belt Line? Although it has “belt line” in the name, the Jackson Belt Line is more of a short industrial branch…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print

Small Layout Meet 2023

The Small Layout Meet is Back! June 17, 2023, 10AM – 4PM Northwest Ohio Railroad Preservation, INC12505 C.R. 99Findlay, OH 45840 The meet will be…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print

Roundup Time! – How Green is Your Railroad?

While doing research on older prototype railroad scenes from the 1970s and before, it is hard not to notice how green many of the old…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print

SmallMR.com is back!!

Well after a month hiatus, I finally have a new server in place and the website is back up and running. The old server had…

Share this:

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to share on Tumblr (Opens in new window) Tumblr

- Click to share on Pinterest (Opens in new window) Pinterest

- Click to share on Reddit (Opens in new window) Reddit

- Click to share on X (Opens in new window) X

- Click to share on Bluesky (Opens in new window) Bluesky

- Click to email a link to a friend (Opens in new window) Email

- Click to print (Opens in new window) Print