October is my favorite time of year with cooler temperatures, the changing of the leaves and the spooky fun of Halloween. So, in keeping with the “spirit” of the season, let’s take a look at the ghost town of Fayette Michigan and the railroad that served it. I had the pleasure of visiting the location recently, so I took some time to research the location and the little railroad that served it.

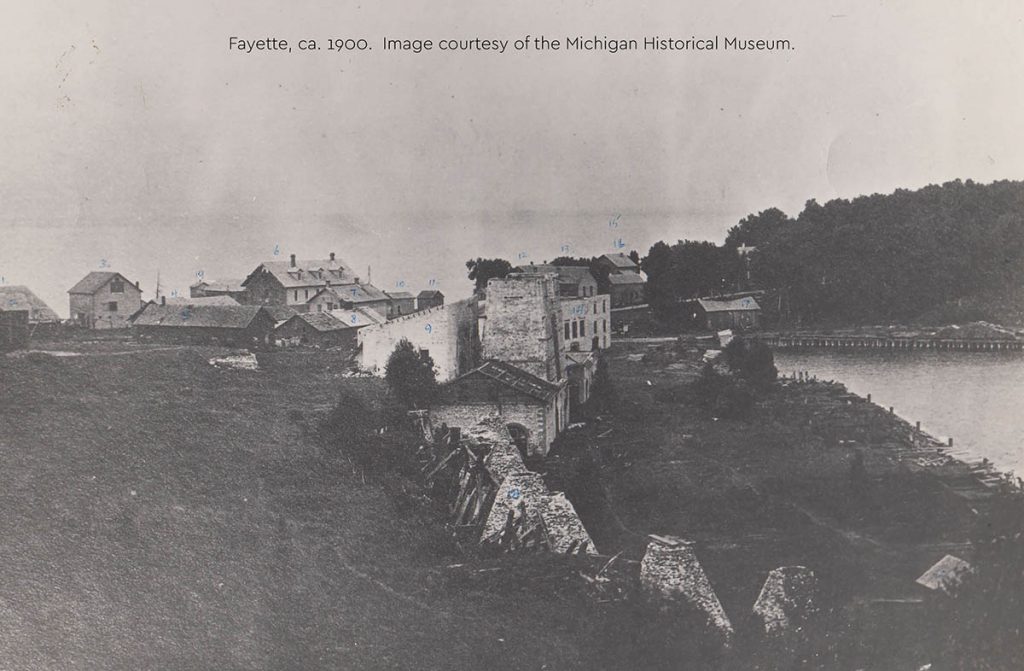

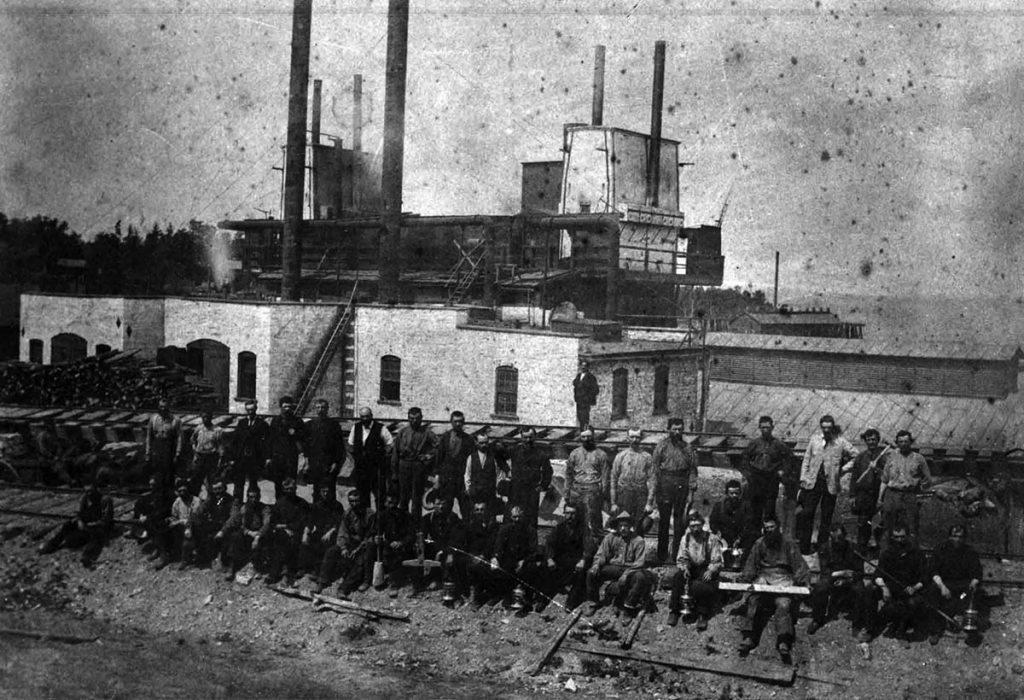

Fayette is a ghost town located on the Garden Peninsula of Michigan’s Upper peninsula (a peninsula on a peninsula). Today Fayette is a state park and historical site complete with a campground and docks for boaters. The town, and the iron smelting furnace it supported, was owned by the Jackson Iron Company which operated from 1867 to 1891. The town was named after the company’s manager Fayette Brown. At its peak the town had nearly 500 inhabitants.

Fayette’s existence was due to the need to smelt pig iron. Fayette was a near perfect location with a deep protected harbor, limestone for furnace flux and an abundance of hardwood forest for charcoal. The iron ore would be mined in the ore fields west of Escanaba Michigan and shipped from Escanaba to Fayette across Big Bay De Noc.

The operation was profitable and achieved a peak production of 16,875 tons of smelted iron in 1884. In the 24 years of operation the Jackson Company produced 229,268 tons of smelted iron but by 1891 with rising costs and competition the furnaces at Fayette were shut down.

Three ingredients are needed to smelt iron, crude ore, fuel to melt the ore and a flux to remove oxides from the ore. From the beginning, railroads have always been looked at as the most efficient way to transport bulk materials like ore, stone and wood. The Jackson Company saw the same right away a small narrow gauge line would be well suited to the needs of Fayette. They situated the furnaces, so they were directly adjacent to the harbor and less than 200 yards from the limestone cliffs (flux). These would be at the doorstep of the furnace and be easily moved in as required. The fuel for heat was another matter. The local forests had plenty of hardwood to make charcoal, but a railroad would be needed for the logging operation and the movement of the finished charcoal to the furnace area.

Although eleven kilns were placed close to the furnace, an extensive network and charcoal kiln sites within a ten mile radius were operated to supply the required fuel. By the mid-1880s, more than 80 kilns were in operation. The process of making charcoal took eight days and required constant supervision. Many Kiln workers lived in small groups outside the town near the kiln sites.

Although the townsite is well documented, information about the railway is few and far between. The historical publication “Upper Peninsula 1869-1873” published by Julius Bien states the following about the railroad and the wood used:

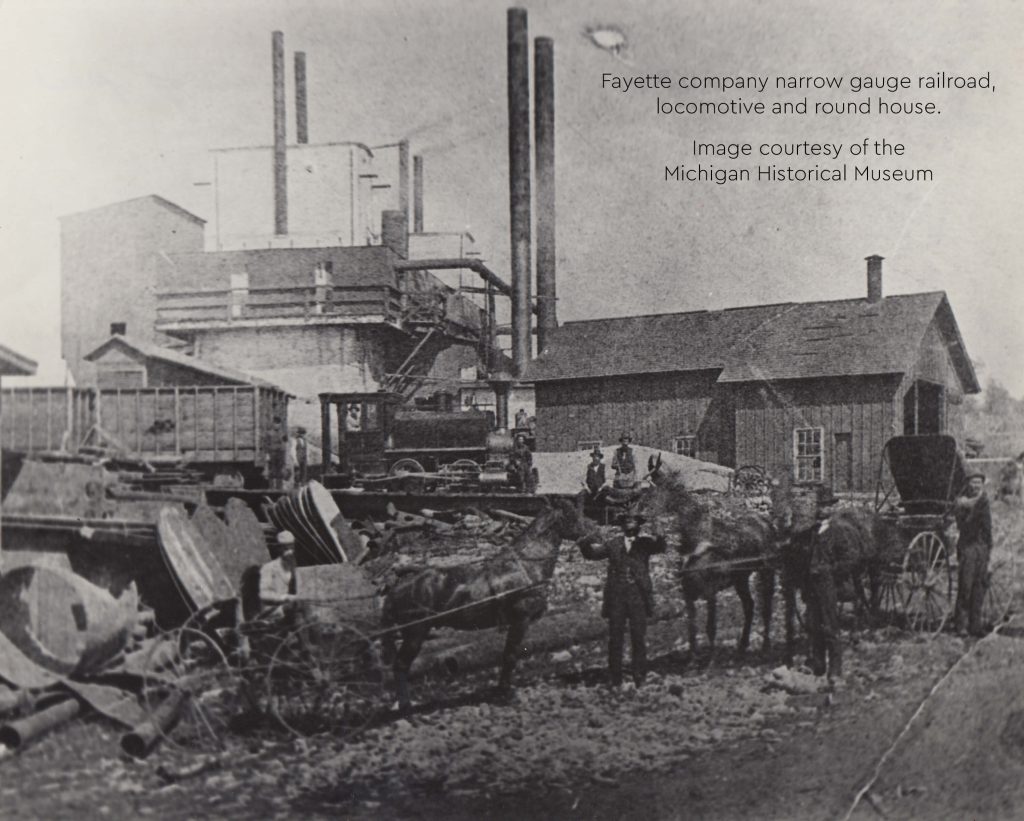

This wood is delivered by the parties of whom it is bought at the furnace , or along the line of the company’s railroad , of which they have constructed for this purpose six miles, laid with T – rail, and operated with two small locomotive engines, it being the only furnace on the Upper Peninsula that operates a locomotive railway for the exclusive purpose of transporting fuel.

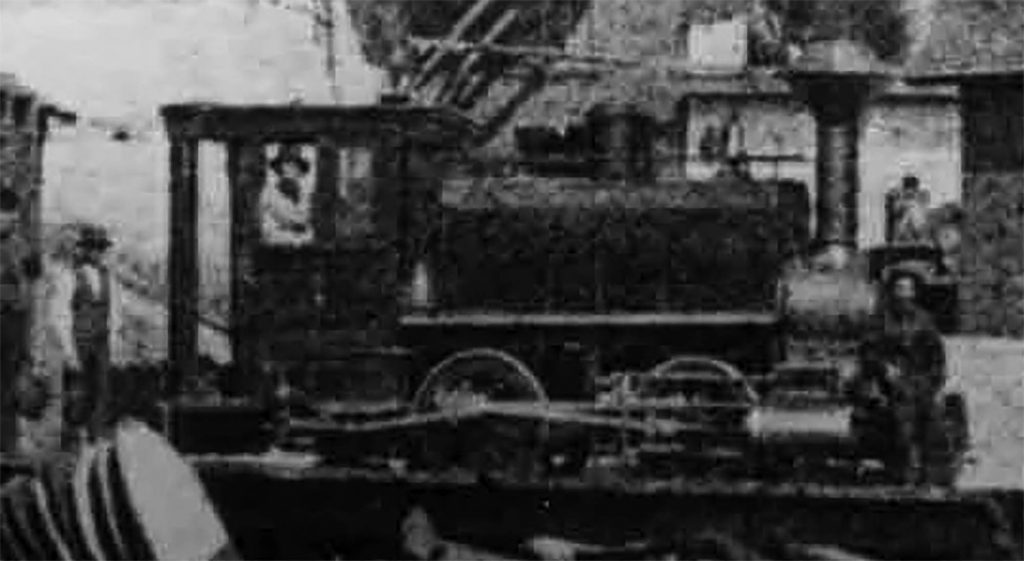

The railroad had two locomotives, both built by the Porter, Bell & Company. These locomotives were the first built by Porter, Bell & Co (after his split from Smith). The locomotives were very small narrow gauge 0-4-0 tank locomotives. I have not been able to find documentation on what the exact gauge of the line was, but we know that during this time Porter was having great success with a 42” gauge 0-4-0T design.

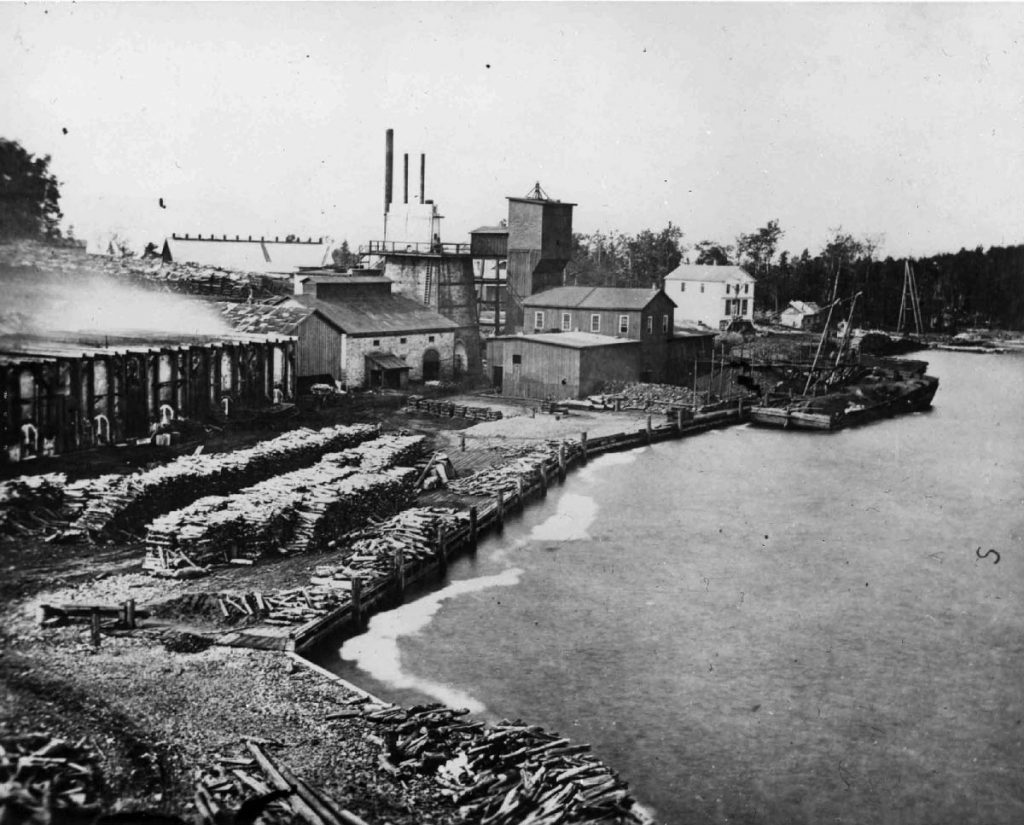

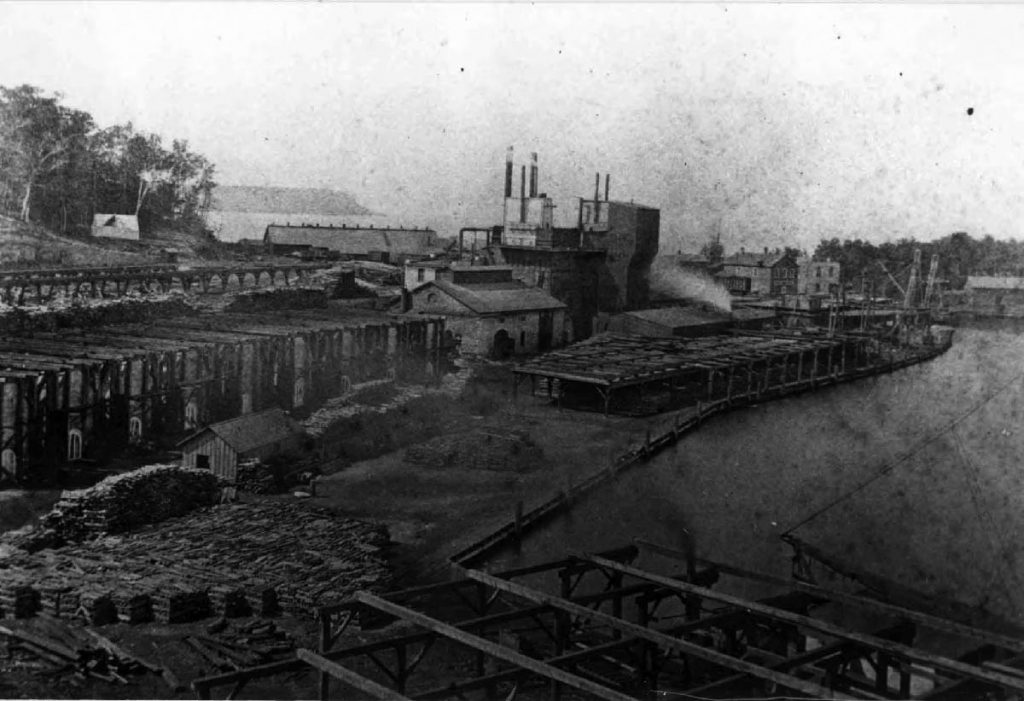

From the available photos of the locomotives, it is very interesting that no fuel bunker can be seen. Perhaps they just pulled wood from the cargo as required? The cars in use appear to have been small flat cars and small 4-wheel jimmies that resemble very tall ore jimmies used in mining operations. My assumption is, the flat cars hauled wood and the jimmies were used to haul charcoal made at the more remote kilns. All the cars used a bogie wheel arrangement with was well suited to very sharp turns.

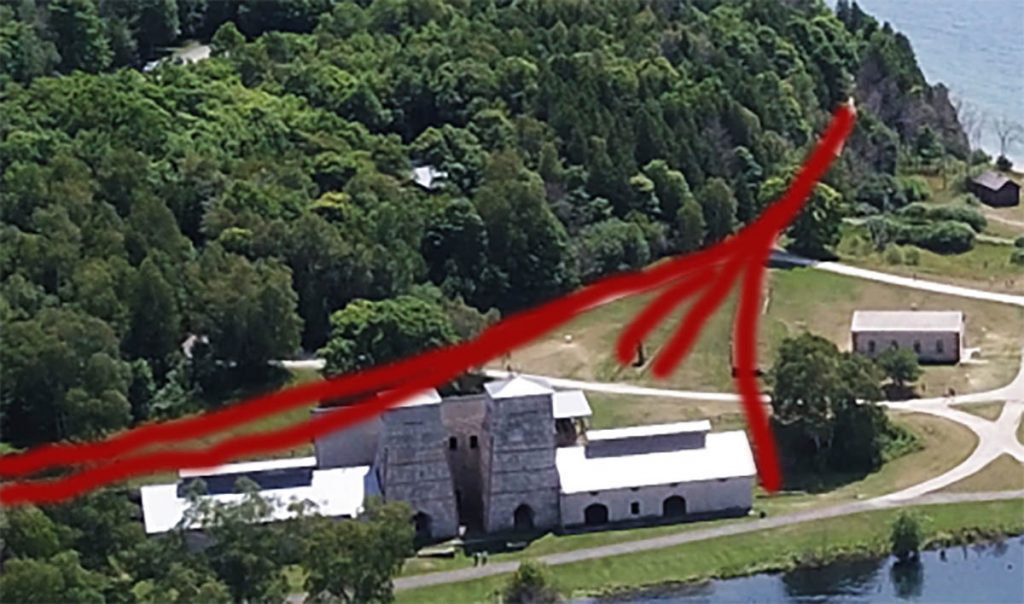

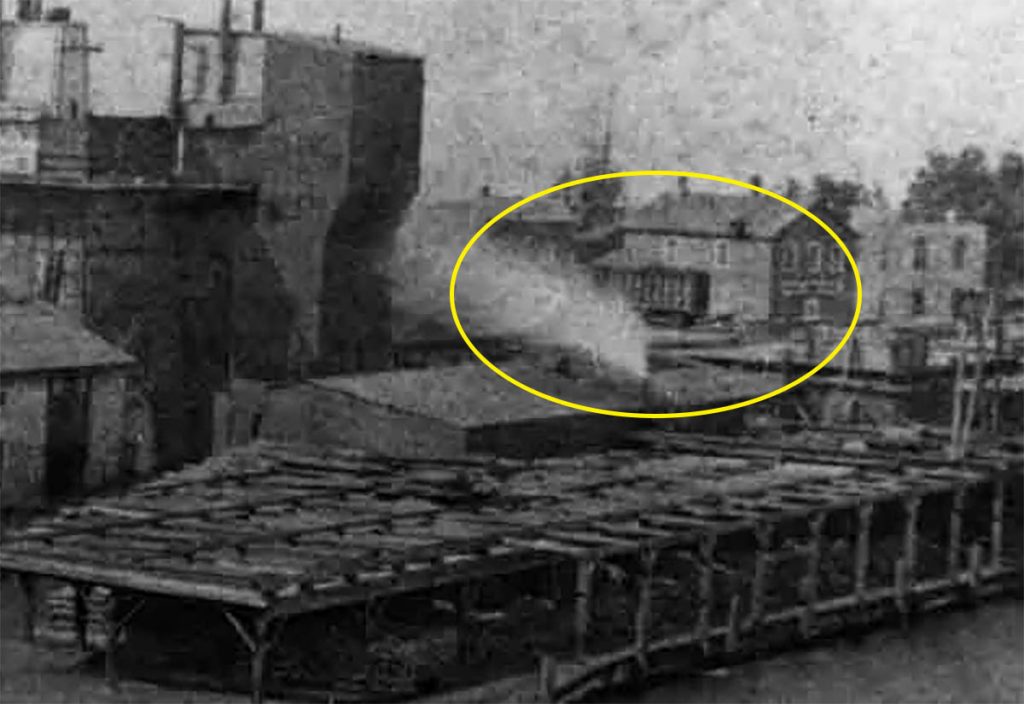

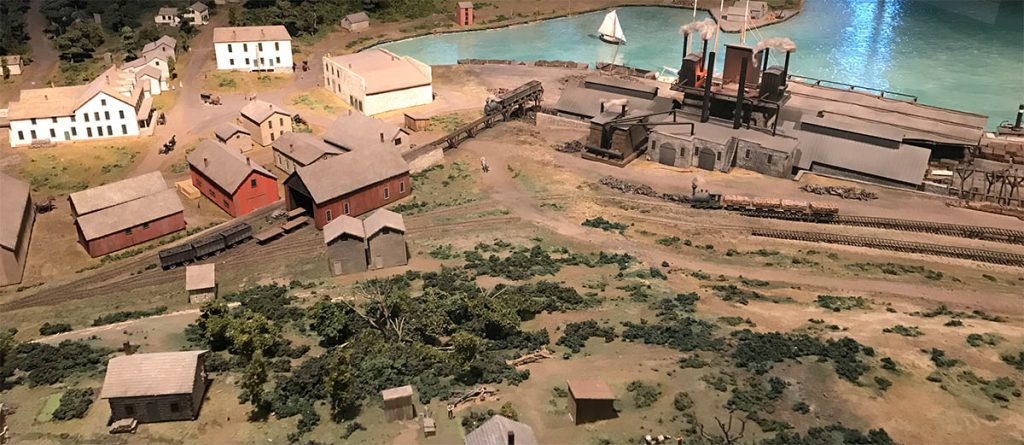

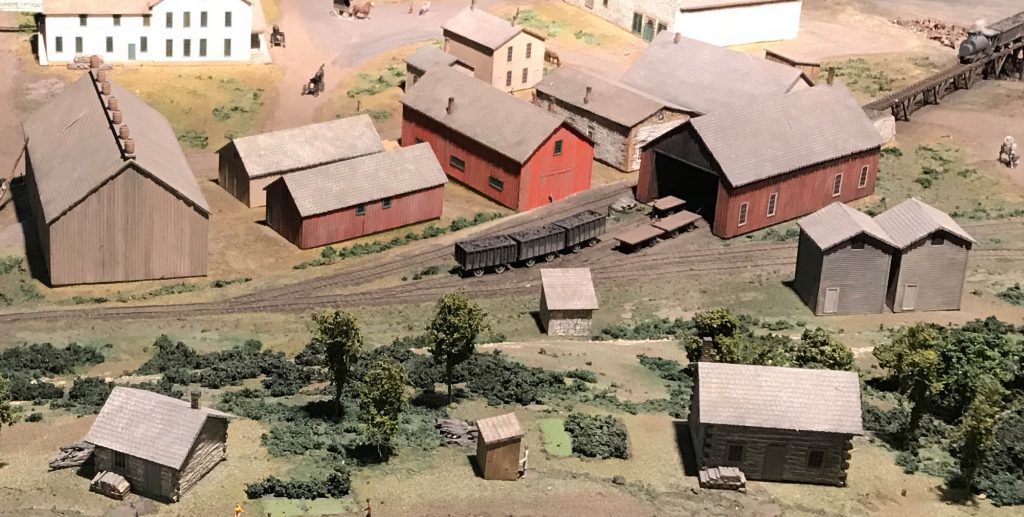

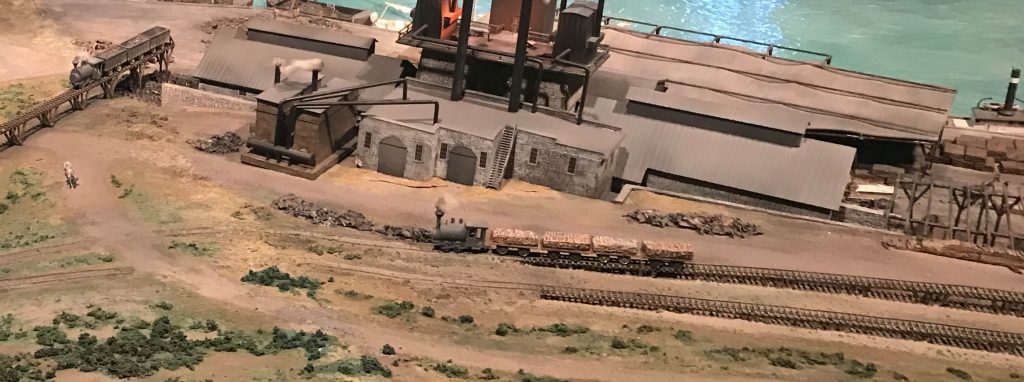

The railroad entered the town from the south passing the cemetery and the church about a half mile outside of the townsite. Once entering the townsite the line splits passing either side of a railroad building (referred to as a “locomotive house” by historians) which contained two or more tracks. No closeup photos of the locomotive house could be found but the diorama at the visitor center shows two tracks entering one end of the building and cars lined up in front rather than locomotives. The building itself was a rectangular shape with a pitched roof with a central ridge. With Michigan’s harsh winter weather, I would assume the building was primarily for locomotives. That said, the diminutive size of the locomotives would have made it very possible that a portion of the building could have served as a car shop as well.

Upon the line splitting around the locomotive house, the left (or South) track continues onto a short trestle which ends alongside the #2 casting room. I have not seen any explanation of what the trestle was used for, but photos of the site show charcoal jimmies on this trestle. The assumption would be charcoal from remote sites was delivered here for use in the furnace. Charcoal made on site was located on the opposite side of the furnaces next to #1 casting room. Since no foundation is evident under this trestle, it appears the charcoal (or other materials) were loaded into carts at this point.

The right (or North) track split into two parallel but widely spaced tracks that went around the rear of the furnaces. These tracks were elevated on a low trestle for some distance and ended near the hill that contained the lime deposits. These tracks fed wood to the kilns located at the furnace location. The kilns were located just below the small hill which supported the trestle. The area below the trestle was a long flat area. Why the railroad was elevated on the trestle over such level flat ground is also a mystery. In photos, we can see large piles of wood in front of the kilns, but this is opposite and below the area where the railroad would unload the wood. Perhaps it was easier to unload “downhill” where the wood is simply pushed off the train on the trestle into a sorting/prepping area below. When needed, the wood was moved to the front of the kiln (again another downhill effort).

According to all historical descriptions, the line was not used for moving the lime. As shown in photographs, a covered area below the cliff was used to store the lime before use. The railroad did not access this area.

With little information on how the railroad operated, there are a couple elements that bring questions. Fayette’s second largest export after smelted pig iron was grain. According to historical reports, the dock area included a grain elevator. I have not seen any evidence of an elevator on the dock(s) but two “granaries” were located directly behind the locomotive house. One must wonder if grain could have been carried from some of the areas that had been logged in the prior years to the town site for loading to the granaries. It seems strange that someone would actually move grain by wagon over several miles when a small railroad was readily available. There is also the question of passengers. The kiln sites, the church and other outlying facilities were along side the small railway. Certainly, there was not any regular passenger service but did anyone try to use it to shuttle people back and forth from the outlying kilns to the townsite?

Modeling the logging and kiln operations at Fayette can be done in a small layout without much effort. Within the furnace area the prototype appears to have only four turnouts total. No turnaround for the locomotives is required and the available documentation does not even show a run-around track. Almost anything could be possible in the logging and kiln areas as no information about those areas could be found at all. A simple, small layout could be done with just the locomotive house, tall trestle and short trestle unloading areas. Short trains of just two or three cars at a time could move through the unloading scene and then disappear into a staging area. If a slightly larger affair is required, very sharp curves could be used to move into a kiln or lumber scene.

A very close stand-in for the locomotive is the On30 Bachmann 0-4-0. Although quite a bit newer than the prototype, the size is very close and would appear correct to all but the wiser in their history. As for the cars, short flat cars with bogie wheels are available in multiple scales. Bitter Creek Models has a HO standard gauge ore jimmie that comes close to the prototype. With the cars so tall and the trestle so small, it is hard to believe people got up there and unloaded these cars by hand. The question here is by 1872 was tipping or side unloading even done? Fayette was know for being very efficient and keeping costs down, could this have been a place of innovation?

Excellent presentation of a most interesting and very model-able setting.

Thank you.

Great research and effort to share with model railroad enthusiasts. The diorama pulls so much together and is a nice look at what is possible for a small layout. Thank you for going thru this exercise. Tom

Thanks for the interesting story! Very well written and great photos!

Phil

I am continually amazed at your creative talents,

A really great story about Fayette.

I did not Fayette existed.

Fayette is a fascinating town. We visited it by boat in 1997 and have yet to return, but some day. When we were there it was a pristine sunny summer day. I can’t imagine how polluted it must have been at its height! Two furnaces, dozens of charcoal kilns, and two locomotives! Your excellent report focused on the railroad, but I found the town to be fascinating as well. I remember a building (town hall maybe?) that had an “opera hall” on the second floor. At that time we could walk up onto the stage, and on the back wall there were still the signatures of many of the performers who played there! The entertainers must have come and gone by boat.

Thanks for the fine story and historical photos.

Phil Doolittle

I agree Phil! The site is almost magical today. We visited on a very sunny October day when the temperatures were about 65. Perfect conditions as far as I am concerned. The place is beautiful and peaceful. I highly recommend if you have not visited before, you should.

Another great article, Marshall!

I am trying to remember if there was a tramway associated with the sandstone quarries around Jacobsville on the southside of the Keweenaw Peninsula. If so, another potential mini-layout!

Sounds like something o look into!

We tolerated heavy fog and found Fayette using Loran during a sailboat cruise in the 80s. Stayed a few days for the history and solitude. It’s a great place to visit, relax and recharge.

Wonderful finding this article. I spent many days wandering around Fayette as a child. Now retired and living in Virginia, I was wishing to incorporate the area in my model railroad. You have made this an easy project to start. Thanks again.

Wonderful idea for a small ng layout!