This months article on building legs includes a couple mistakes or where I did not follow the original design. We have to realize that making mistakes is part of the learning process.

After the first setup with the Boat Yard in Flint Michigan (yes I missed the National Show with it) I have a few revisions to make. The way i setup the servo throw wires worked great in practice but after a bumpy ride in the vehicle to get to the show, some of the wire had dropped and fell out of the holes. When powered they started pushing up on the turnouts and almost caused some major issues with the track. I will write up the changes and add them to the post on servo control in the near future.

The Boat Yard when assembled is 25 feet in length. This is much larger than i can assemble in my home at one time. The show in Flint was the first time I had been able to see the whole thing together. Normally, I would assemble all parts and thoroughly test them together before the show. That was not possible here and issues did arise.

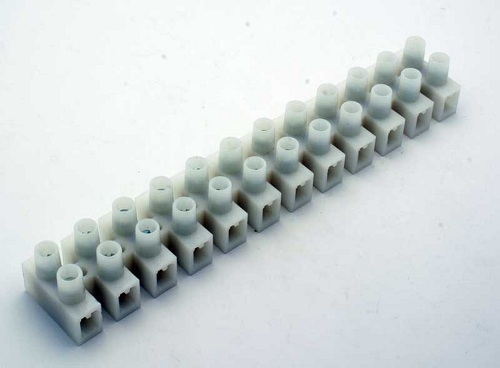

Another issue at the show was a power failure on three of the modules. This was caused by a new type (European style) of terminal strip. Again the ride to the show showed where all the loose stuff was and made a mess of it. I will be replacing all of those strips with traditional terminal strips.

Lessons learned and i will incorporate these into future articles.

Gidday Marshall, even though you’ve encountered a few teething issues, I must say that as it stands the set up looks rather impressive. I’m afraid to admit I’ve been sitting on my hands regarding my ferry yard and to make it worse have yet to “finish” the ferry which when I consider that I’ve got less than 3 hours work to do is not great. I’m going to run out of excuses soon!!!

Thanks for sharing your efforts,

Cheers Craig..