There has been a lot of conversation in the forums about using Gator Foam, Foam Board, Insulation Foam and the pros and cons of each for layouts. I decided to break out my old Bakersville Layout and see how it was holding up.

I started Bakersville two years ago as an On30 test layout. I had seen discussions back then on using Foam Core and decided to try it out. The material is very inexpensive, stiff and lightweight. It will crush if you step on it or ding a corner if dropped. It will easily support the weight of model railroad locomotives and rolling stock.

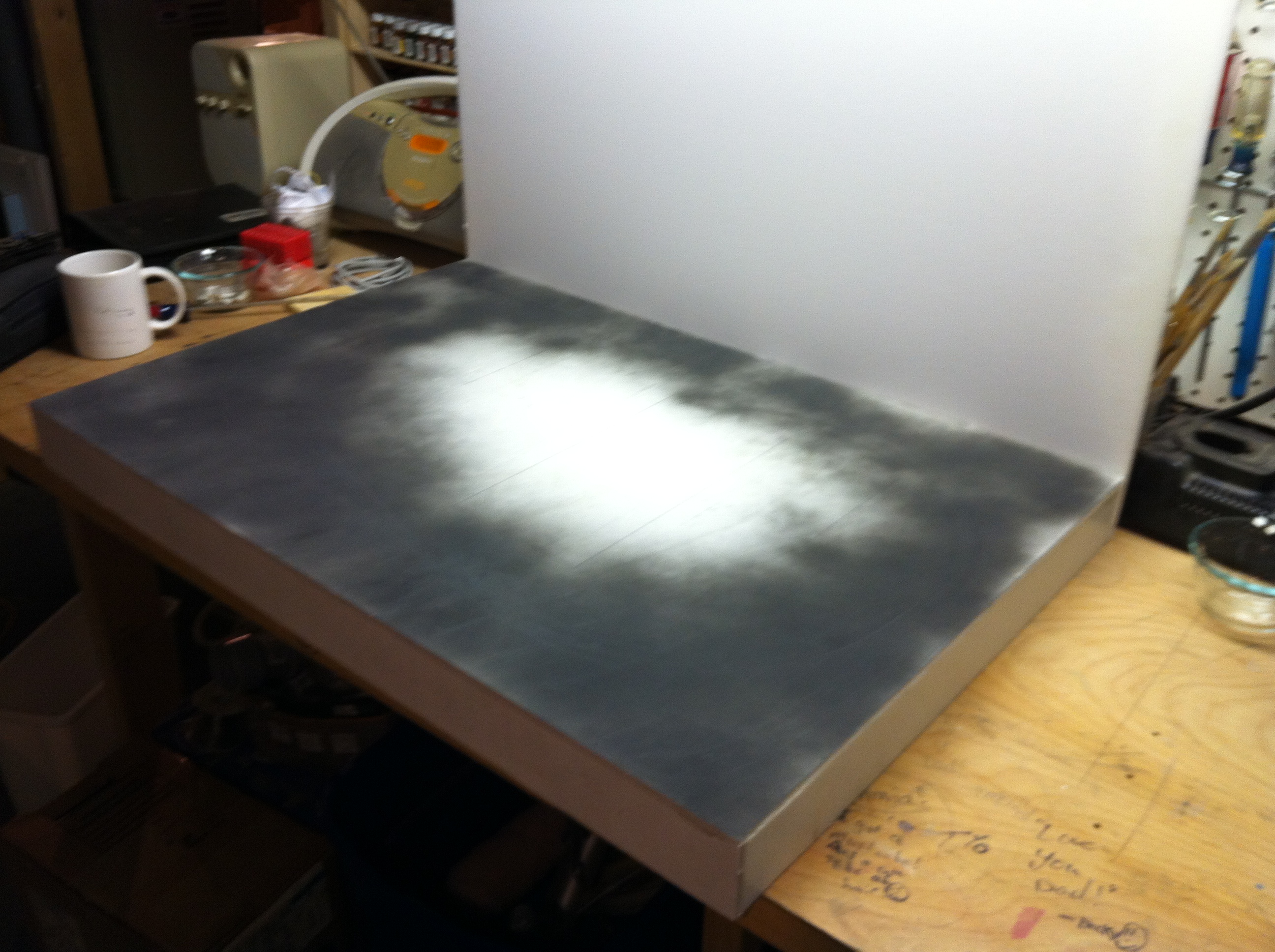

I made the base for the layout from 30″ x 20″ pieces I picked up at Michael’s on sale. This is the cheapest of the cheap foam core. As with any material, the foam core requires support members much like the joists under the floor of a house. I took one of the pieces and cut it into 2″ strips. I used the strips to frame the ends and create joists underneath. I used hot glue to assemble the pieces. I painted a portion of the top flat black where the tracks would be placed. That is as far as the project had progressed due to other projects taking precedence.

As I stated, the base was assembled two years ago and has been stored in a Michigan basement the entire time. For those who do not know, Michigan has the ability to go from 10% – 90% humidity and our annual temperature may also deviate 100 degrees in a season. After two years the layout and foam board is just as flat as the day I assembled it. Is all the foam board in my basement flat? No, I have many pieces that have degraded and are no longer suitable. The difference is the assembly method used. The use of cross members keeps the top board in place and flat. This same principle applies to most porous materials. I have seen numerous times, modules and layouts made entirely of 3/4 plywood or other heavy materials with the belief it will have less tendency to bend or bow. Simple techniques can eliminate the need for such “heavy” materials. Using “L” or “T” construction techniques allow for the use of lightweight materials and will achieve a stronger structure. Much of the conversation in the forums has been centered on how the material bows when painted or is exposed to moisture. I think how Bakersville has held up shows that with proper technique, plain cheap foam core will maintain shape and serve well in various climates.

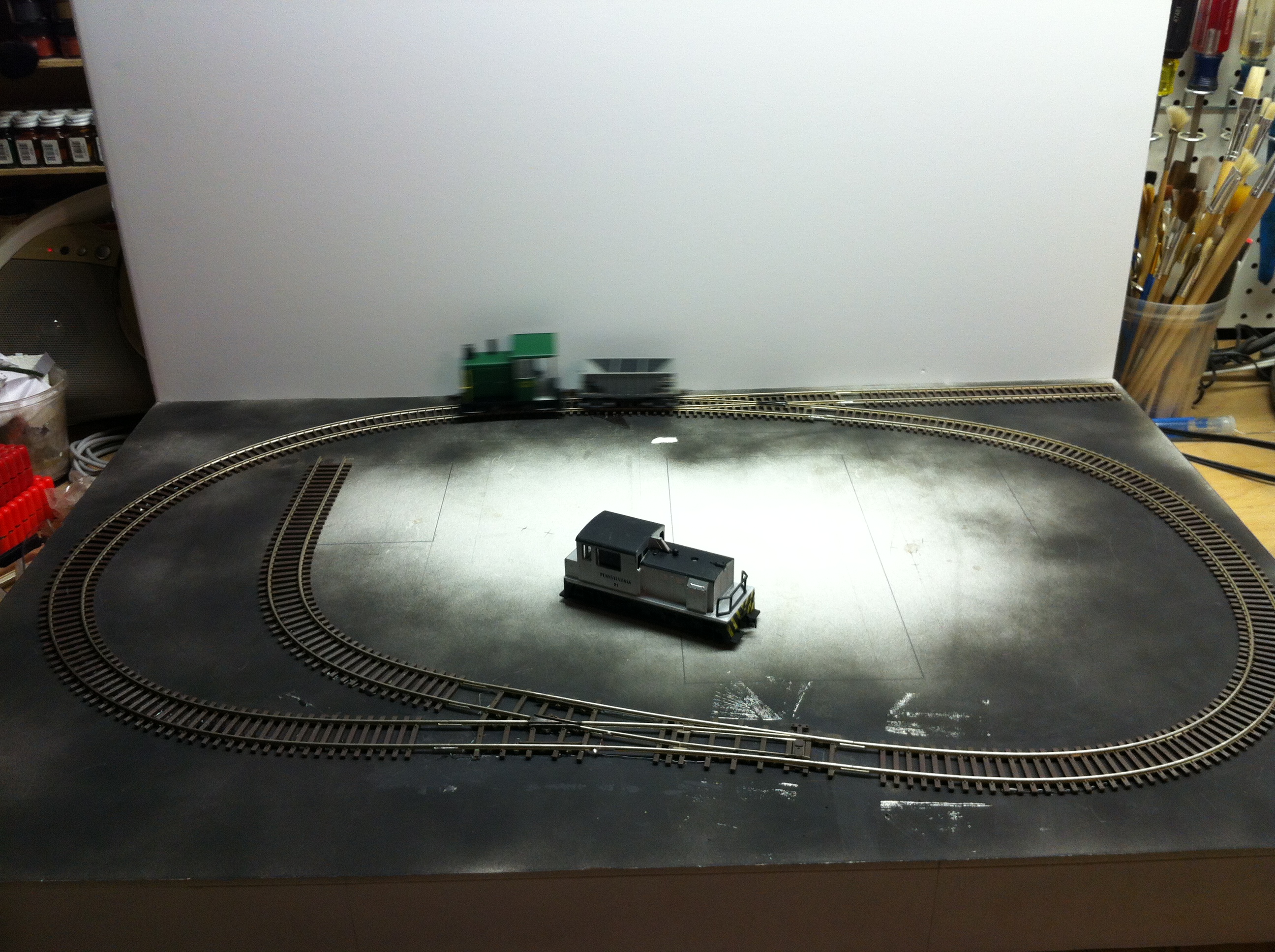

With the dust brushed away and a need to do something, I decided to lay the track and move forward with the next phase of Bakersville. I had a large stockpile of HO scale code 83 track laying around from a previous layout and I decided to put it to use. I want the finished scene to have cobblestone streets and an industrial look to the layout so in most areas the ties will be covered and not seen. To keep things simple I used some old Atlas code 83 turnouts. I cut away many of the ties in the “Y” turnout since it is at the front of the scene and might show some of the ties.

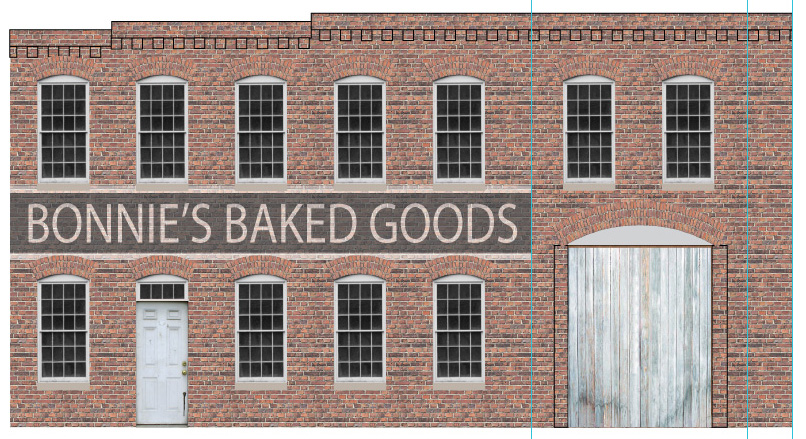

The track plan is a basic oval with two trailing point turnouts. The run-around will be hidden by buildings when completed. The rear track will act as staging. When completed, it will appear as a street scene with trackage between three buildings. Cargo will move between the buildings to support the manufacture of baked items (this is Bakersville after all). The intent is to create cardstock structures to create a cityscape. I had already created one structure two years ago called Bonnie’s Baked Goods after my wife.

My new (old) layout inspired my son Andrew to want to play with the trains a while.

After some discussion we decided he needed his own layout. We had just cleaned out the storage area and had uncovered an old Thomas the Tank train table that had not been used in some time. We took some more of the old track and using the same plan as Bakersville cobbled together a slightly larger 32 x 48 version for his toy soldiers. He needs more cars but now he has a reason to go with dad to the train shows.

For now Bakersville will go back into storage as other projects take priority again. Maybe in another two years we will see how the foam core is holding up again.

I built a foamcore module when I was a member of a club in Sacramento almost 25 years ago… The layout was 2′ by 4′. It was a “learning experience” but once the “bugs” were worked out of it, I kept it and used it for almost 20 years. It was still serviceable when I threw it away for lack of space to keep it. Enjoy your layout… Foamcore is fun!